Storage Tanks

Why Coating Monitoring is Critical for Storage Tanks

Storage tanks are exposed to a combination of chemical, mechanical, and environmental stressors, including aggressive contents, moisture, UV exposure, and temperature fluctuations. Internal and external coatings are the primary barrier against corrosion, but over time, factors like water ingress, chemical permeation, and cyclic thermal loads degrade their protective function. If left undetected, this degradation can lead to underfilm corrosion, coating disbondment, reduced structural integrity, and eventual failure. Visual inspection and thickness checks often fail to detect early-stage degradation, making more advanced assessment methods essential.

EIS is recognized by the EEMUA and has been added to the EEMUA 159, 6th Edition Learn More

CQM: In-Field Electrochemical Impedance Spectroscopy (EIS)

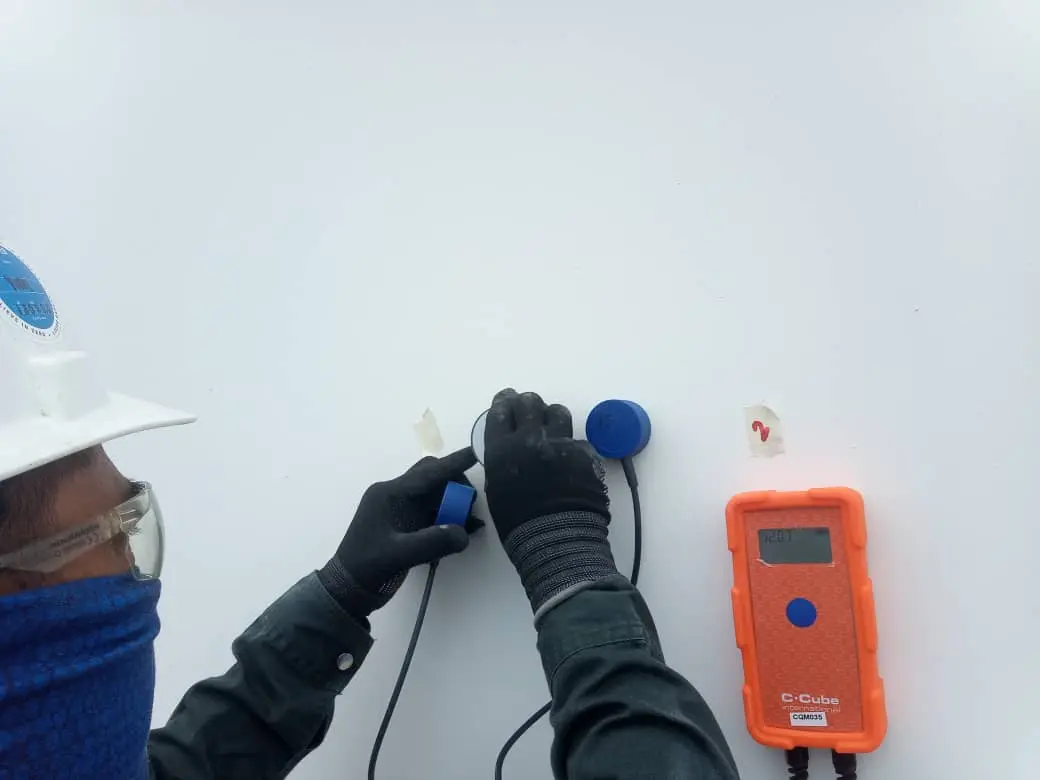

The Coating Quality Measurement (CQM) uses Electrochemical Impedance Spectroscopy (EIS) to non-destructively assess the functional performance of protective coatings. The sensor evaluates how well a coating still acts as a barrier against corrosive elements. Each measurement takes just 1–2 minutes, making it ideal for tank inspections where efficiency and actionable data are critical.

Photo provided by our partner Abadi Oil & Gas Services (Malaysia)

Beyond DFT: Quantifying Functional Performance

Dry Film Thickness (DFT) is commonly used to verify application uniformity, but it does not indicate whether a coating is still providing protection.

CQM complements DFT by measuring the actual electrochemical barrier properties of the coating in its current state. This allows asset owners to:

- Detect degradation invisible to DFT or visual inspection

- Assess remaining protective function, not just thickness

- Identify localized coating failure risk early

- Improve root cause analysis in failure investigations

Used together, DFT + CQM offers a complete picture: thickness and functional performance.

Applications in Storage Tank Maintenance

- In-service coating condition assessments (external tank shell, roof, base)

- Assessment of internal linings during empty-tank maintenance windows

- Performance verification after coating repair or application

- Mapping degradation over time to support RBI or inspection intervals

- Comparative studies between coating systems or application methods

- Support for fitness-for-service evaluations and lifetime extension strategies

Extend Coating Life, Reduce Risk, Lower Cost

The CQM sensor empowers asset owners to transition from reactive to predictive maintenance by quantifying coating degradation early, before failure occurs. This leads to:

- Optimized coating repair timing

- Lower total cost of ownership

- Enhanced safety and environmental compliance

- Improved documentation for audits and fitness-for-service justifications

Get Coating Insights Before Your Next Inspection

Contact us to learn how CQM can complement your inspection workflow with objective, in-field coating performance data.

Contact us